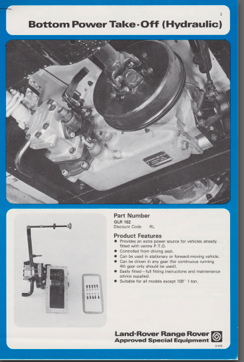

Bottom PTO

The purpose of the Bottom Power Take Off (BPTO) is to allow an additional PTO output when a centre PTO was already fitted. The BPTO bolts neatly to the underside of the transfer box, replacing the bottom cover plate and taking its drive from the transfer box intermediate gear.

The first BPTO released was the hydraulic output type in July 1963, followed by the mechanical output version in June 1964. The hydraulic BPTO could be used for one of two applications. The first application was to operate the Land Rover hydraulic winch and therefore leave the normal PTO position free to drive a centre or rear PTO. The second application was to enable further hydraulic equipment to be used if the vehicle was already fitted with another hydraulic system. The mechanical output version could be used to power such things as a compressor or generator mounted within the rear of the vehicle when the existing centre PTO was already in use. In the present day, the BPTO is particularly useful when both an overdrive and hydraulic winch are fitted.

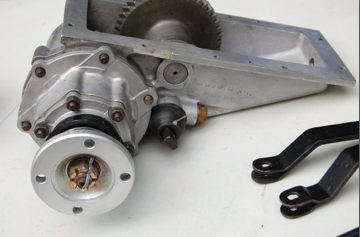

Due to the

gearing of the BPTO, the output of the BPTO rotates in the opposite direction to

the normal centre PTO position. This means the Dowty supplied hydraulic pumps

need to be of the correct rotation. Hydraulic pumps should be stamped with a letter

‘A‘, which shows the pump is the correct anti-clockwise rotation. Early pumps

are non-reversible but the later smaller pumps from the late 1970’s onwards can

be reversed, however if the pump shows signs of wear it is inadvisable to do so.

The mechanical output is a standard centre PTO but if attached to a rear PTO,

the rear PTO output shaft will also turn in the wrong direction. The BPTO can

be engaged separately to the centre PTO by depressing the clutch and pulling

out the selector lever, which protrudes from the heel board, left of the

transmission tunnel.

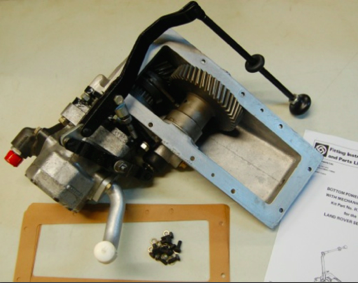

The BPTO was

manufactured by Aeroparts Engineering and remained in production until the

demise of the company in the mid 1980’s. The unit remained virtually unchanged

throughout its production life with only a few minor modifications, mainly to

the selector levers. The Dowty hydraulic

pump was changed in the late 70’s to a newer smaller design in line with the

standard hydraulic PTO.

Early BPTOs are

stamped with AEH.BPTO.*** with later ones stamped AEH.BPTO.MD.*** or

AEH.BPTO.HYD.*** denoting the output type. Very late BPTOs had a green

Aeroparts manufacture plate stuck to the underneath of the unit.

The BPTO was popular

with the many companies specializing in industrial and fire appliance

conversions, such as Broom-Wade and Air Drive, who created an under-floor compressor

vehicle and a backhoe digger conversion. The presence of a BPTO on a Air Drive

Compressor vehicle allowed the fitment of a hydraulic winch in addition to the

compressor, allowing the vehicle to be used for more than one purpose.

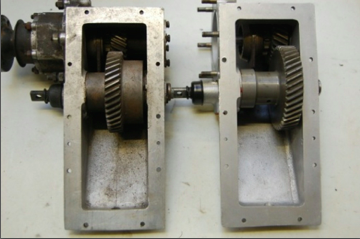

A bizarre twist was the availability of a BPTO to fit the ‘One-Ton’/Forward Control ‘all-helical’ transfer box. No written evidence has come to light to officially state these were available, however a small number are known to exist. These units can be easily identified by the teeth of the drive gear been central to the unit as well as the output been of the ‘One-Ton’ type.

The BPTO was always an expensive accessory,

costing £80 in 1967 when a Regular Short Wheelbase petrol cost £710! It was therefore

only fitted to vehicles where the additional output was a necessity and the

benefits outweighed the costs.