MAP / Fairey Free Wheeling Hubs

Fairey Free Wheeling Hub Parts Book & Fitting Instructions. (DOWNLOAD)

Probably one of the most popular accessories still fitted to Series Land Rovers today are freewheeling hubs (FWHs). Over the years there have been many manufacturers of FWHs ranging from AVM to Warn however, the most popular, especially within the Home Market, were the Land Rover approved hubs manufactured by Mayflower Automotive Products (MAP) and later Fairey.

Land Rover owners have debated the advantages and disadvantages of FWHs since

the day the first sets became available. The manufactures claims make perfect sense

that by disengaging the front wheel hubs from the rest of the transmission while

in two wheel drive, less mechanical drag is created with the resultant increase

in fuel economy, decrease in acceleration times, less mechanical wear, noise

and lighter steering.

The idea of fitting free wheeling hubs to the Land Rover came in the

late 1950’s towards the end of Series I production. Freewheeling hubs had been

a popular accessory in the Untied States for the Jeep for sometime. The first

hub to have approval from the Rover Company was a hub manufactured by the Barton

Motor Company, Plymouth but the rights to manufacture the hub appear to have

been soon sold to Mayflower Automotive Products (MAP) of Tavistock, Devon. Some

of the earliest hubs manufactured by MAP were also fitted to the Austin Gipsy.

These very early hubs differed in external appearance to the later hubs as they

had a slot rather than the protruding ‘nut’ within the actuator assembly.

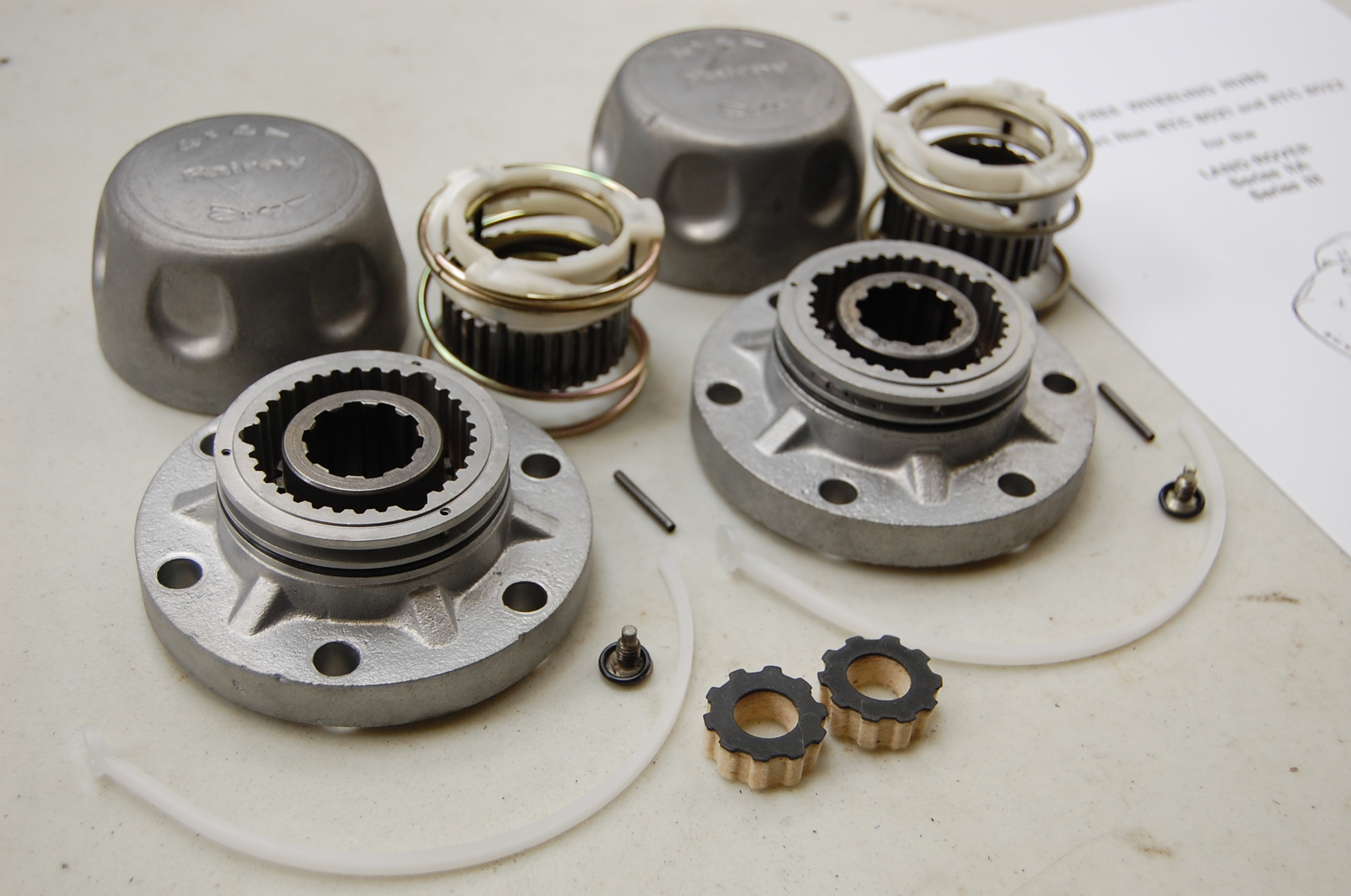

The MAP hub most people are familiar with has an outer aluminium casing

with an inner hub made of steel running within a bronze bush. The hubs are

engaged by turning the centre actuator ‘nut’ a quarter of a turn. This nut was

conveniently the same size as the early Land Rover wheel nut and allowed the

wheel brace supplied with the vehicle to be used. The turning of the ‘nut’

actuates a cam allowing the sprung loaded pawls to engage into the steel inner,

thus locking the hubs in the ‘engaged’ position. It is advisable to rock the

vehicle, if the situation allows, until the pawls can be heard engaging with a

click, otherwise if driven away enthusiastically, the pawls would snatch into their

locating slots and damage the hubs. To disengage, the nut is turned in the

opposite direction and the cam pushes the pawls back into the outer aluminium

casing, thus allowing the steel inner hub to rotate freely. Although the design

didn’t change much over the 12 years or so they were in production, there were

a few minor modifications worth noting. First of all, the outer cap and

actuator assembly on very early hubs had a more detailed casting with sharper

edges. In the middle of the actuator ‘nut’ there was an etched brass decal of

the Mayflower sailing ship that was adopted as the company’s logo and the

wording was highlighted with red paint. Slightly later castings have more

rounded edges and the decal was deleted. Early hubs can also be identified

externally by the presence of an oil filler plug behind the mechanism to

replicate the plug in the axle drive member it replaced. Internally, the

actuator has an O-ring acting as an oil seal with an additional fibre dust

seal. The oil filler plug was deleted on later hubs, just like the later axle drive

members. At the same time, a single seal replaced the separate O-ring and dust

seal and the wording was no longer highlighted. Twenty-four spline hubs were

also manufactured, but they are less common than the 10-spline type due to only

being made for a comparatively short length of time following the introduction

of the Series III long-wheel base with 24 spline half shafts. An early problem soon identified by Rover was

that with FWHs in the free position, the swivel pins within the swivel housing

were not been lubricated sufficiently enough, leading to premature wear. As a

result Rover issued a Service Bulletin recommending that the hubs should be

‘fixed’ periodically to allow the pins to be lubricated.

Another FWH introduced in the mid 1960’s by MAP was the automatic hub. Again the principles were the same as the manual engagement type however once four wheel drive was engaged, the hubs would engage and disengage automatically. This was achieved by friction clutches that engage 12 rollers working between the inner surfaces of the hub and a corresponding number of inclined planes on the central gear. The hubs would automatically engage in both the forward and reverse direction. However the disadvantage of this type of system meant that in overrun, the front wheels would free wheel and engine braking would only be effective on the rear wheels. The manufacturers were well aware of this and recommended the fitment of the manual type hub if towing heavy loads or four wheel engine braking was deemed essential. It appears that these hubs did have a couple of modifications during the production. One of these was the deletion of an ‘out/in’ screw on the side of the main body of the hub and a modification to the roller assemblies. Unlike the manual type they were of an all steel construction and had a pressed steel cover plate that carried the company’s logo.

In 1972, Fairey bought MAP and began marketing both types of hubs complete with the Mayflower branding cast into the hubs. On Valentine’s Day 1974, Fairey were awarded the Automobile Association Seal of Approval for the manual type hubs. The test and resulting report published by the AA concluded that petrol consumption gains ranged from 4% to 19%, depending on the type of vehicle, load and use, with owners who made short journeys in lightly loaded vehicles benefiting the most. A reduction in noise was also noted along with a slight decrease in top gear acceleration times. No lightening of steering effort could be detected and unfortunately the tests were too short when it came to evaluating tyre or transmission wear.

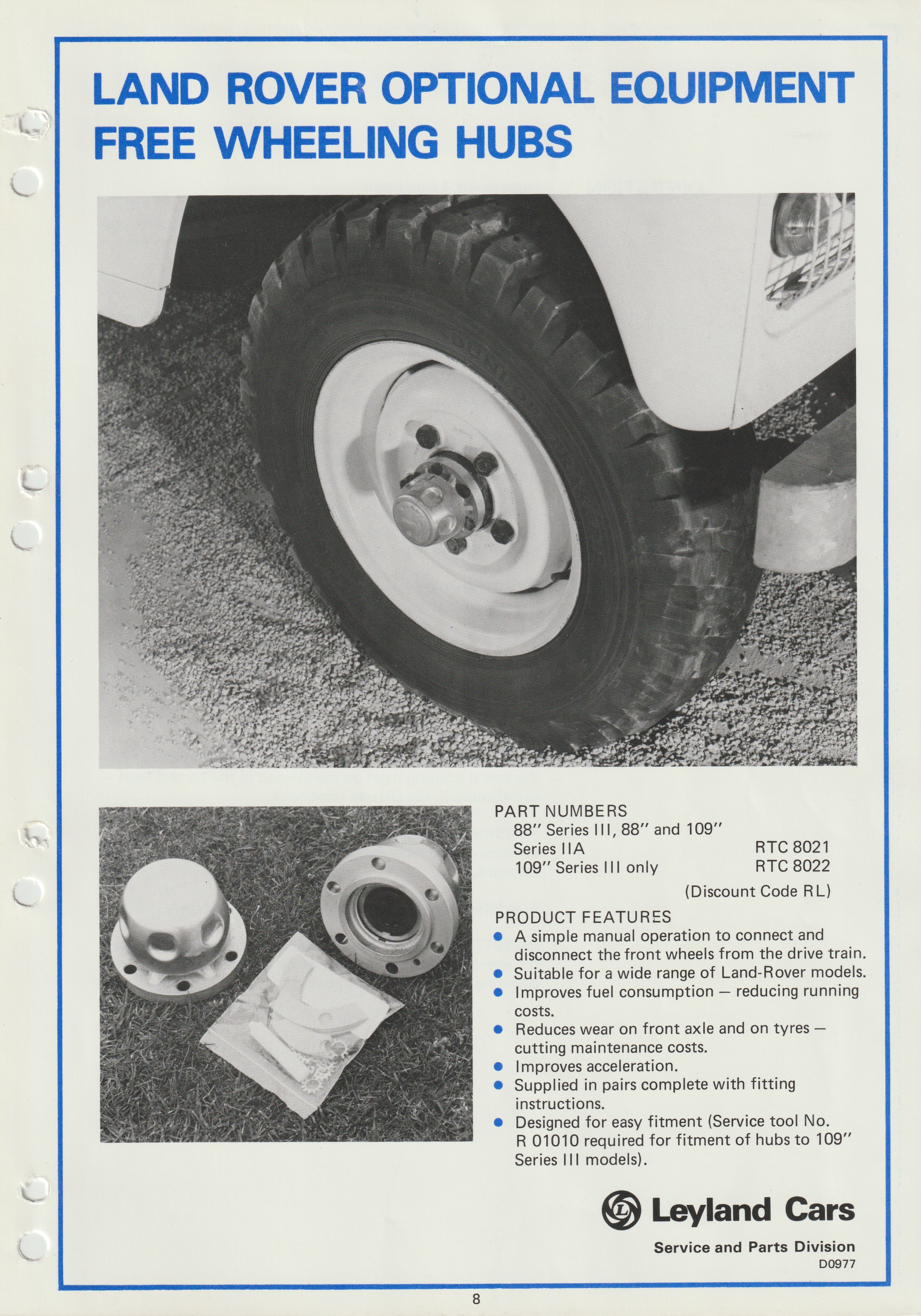

By the mid 1970’s, Fairey had replaced the aging MAP hub with an all-new design. Their new design could be engaged by hand without the requirement for tools and deleted a number of moving parts that were prone to wear. The hubs stuck out from the side of the vehicle less then the MAP hub and therefore were less likely to be damaged while off-roading. They had an intriguing method of being fitted, using a nylon insert that to the uninitiated can cause problems when removing the hub for servicing. By turning the outer cap, three axially mounted cams cast into the end of the cap, pushed the actuator assembly against the spring and engaged it into the drive member, locking the hubs.

The new Fairey design proved popular with Land Rover owners in the oil crisis of the 1970’s when they tried to make their Land Rover as frugal as possible, so much so that by the early 1980’s the Fairey hub became a factory fit option. With the introduction of the Land Rover One-Ten in 1983, Land Rover decided to keep a selectable 4x2 option alongside the permanent 4x4 vehicle and Fairey produced a set of hubs to fit the new vehicles. Although they looked similar and shared many components of the Series version, the drive members had five mounting holes and the flange was made thicker to accommodate the drive shaft ends. They also had a smart black anodized finish.